Advantages of Alumina Ceramic Setter Plate

Long service life (Cost-efficient) Long service life (Cost-efficient)

|

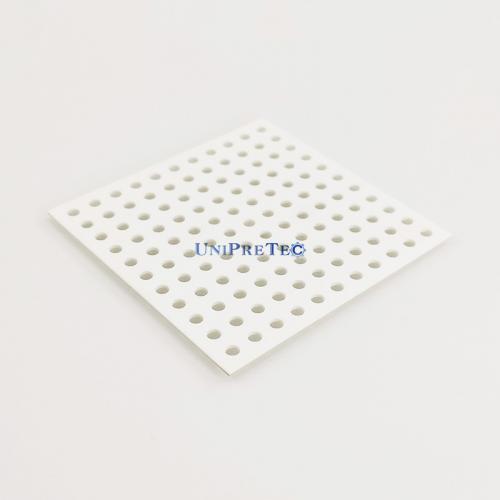

Good flatness and smooth surface Good flatness and smooth surface

|

Good chemical inertness Good chemical inertness

|

Excellent thermal shock properties Excellent thermal shock properties

|

High working temperature (up to 1650 degree C) High working temperature (up to 1650 degree C)

|

... ...

|

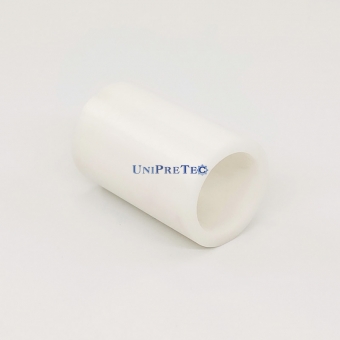

Alumina setter plates outperform greatly over graphite or tungsten setters.

- High purity alumina material prevents foreign substance and will not contaminate sintering components.

- Because of high thermal resistance, our alumina setter plates can be used at temperatures up to 1600°C, and can effectively prevent undesirable deformations after long time processing.

- The property of small thickness will definitely save room of sintering furnace. This enables energy and cost-efficient.

- Lower surface roughness makes it possible for sintering components to achieve uniform shrinkage during firing process, thus helping to preserve the shape of the products. And smooth surface also help sintering components keep good flatness.

- Ceramic setter plates make using releasing agents or protective layers such as coatings obsolete, because there are no contact reactions with metals. Thus, these setter plates also have a long lifetime and do not require reconditioning. For example, molten metals cannot wet alumina setter plates. Alumina purity > 99% can be used both in protective gas atmospheres and reduction atmospheres. It’s also stable in reactive atmospheres and in hydrogen atmospheres.

The setter plates can be used in ceramic injection molding (CIM), metal injection molding (MIM) and low temperature co-fired ceramics (LTCC).

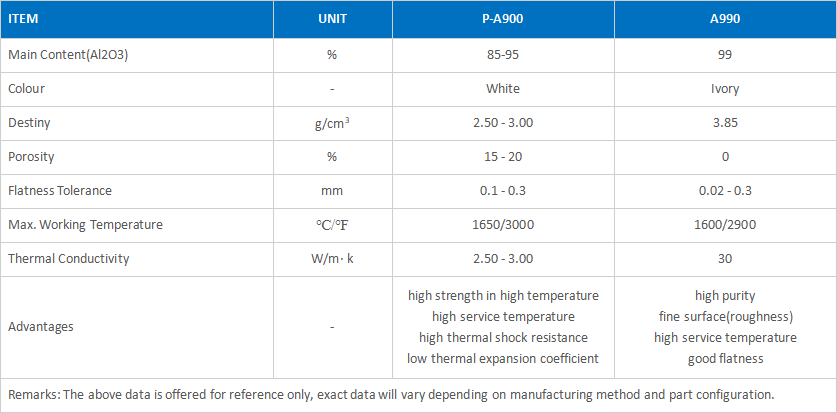

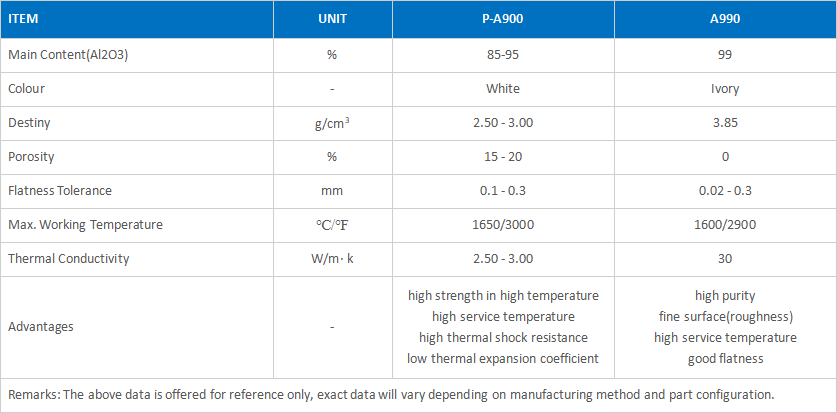

Technical Materials Properties of Alumina Ceramic Sintering Trays/Setter Plates/Saggers